Within an Industrial world that is becoming ever more complicated, technology is an enabler. It lets us gather and make sense of information in new ways, causing us to make better choices about how we conduct our companies. Choose the Industrial Internet of Things (IIoT) for instance)

Below a century we have seen the industry change through the next industrial revolution. The most recent progression, Industry 4.0, introduced the concept of the wise factory. Now we are reaching the tipping point in which technology is old enough to make this vision happen on a worldwide scale.

We have come away since Industry 2.0

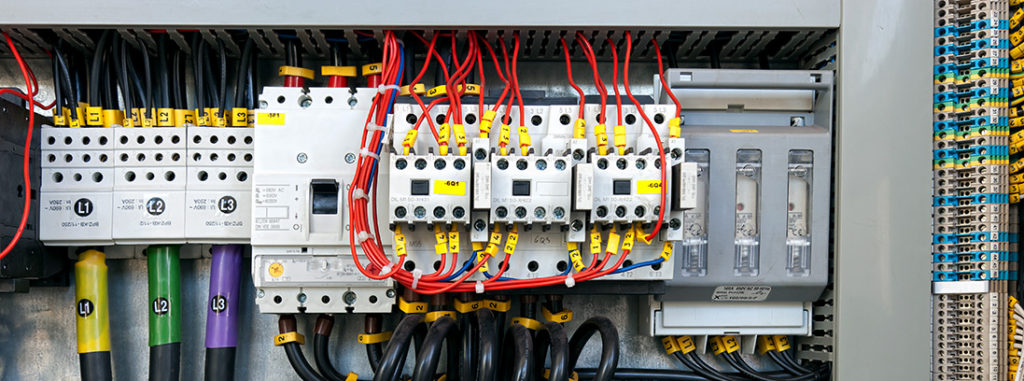

Should you return long times before PLCs were all around, we’d timers, relay, and electrical loop controls. Process control systems have been distributed and hardwired to the mill. Tracking the systems was time-consuming and might frequently need technicians to walk around the mill day long. As you can imagine, this left error finding very hard. Definitely a critical issue for high-value companies where downtime can cost tens of thousands of dollars. This spurred an increasing requirement for the integrated controller. Because of this, engineers started searching for a trusted choice to relay logic. From this emerged programmable logic controls, or PLCs.

PLCs Used to be so large that companies would install PLCs in central control rooms because of their size and ecological conditions. They have been wired into field devices using substantial quantities of cable. Despite the extra cost, PLCs created a massive effect. Faults were easier to locate, downtime decreased, throughput improved and security-enhanced. In the long run, it came down to making a company more profitable, and also the PLC attained that.

The tipping point for the Industrial Internet of Things (IIoT)

Thank you to the evolution in engineering, PLCs have steadily decreased in size, price and therefore are capable of working in more rigorous environments. This has introduced new opportunities to grow the degree of management. We could connect together all of our machines, in numerous factories, in any region of the planet. These machines can conduct a master app fed by a smaller central control to person PLCs. For less complex procedures, a very simple outboard PLC onto a system eliminates the requirement for complicated and expensive electromechanical choices.

More Companies are going to have the ability to gain from the Industrial Internet of Things (IIoT) as the technology becomes more economical. As an example, specific low-cost AC drives come with an onboard PLC at no additional price. It has to be quite attractive to OEMs.

One of the Significant Advantages of utilizing a decentralized PLC

- Large PLCs can be costly. 1 choice is to eliminate the central control and spread the work across smaller PLCs. The price may be further reduced by employing an AC drive with onboard PLC..

- When Updating or creating a switch to a system, additional coding may be deemed necessary. On a centralized control system, this may mean shutting down a complete production line. The other solution is to get a local control which may be dispersed, leaving the remainder of the lineup to keep moving.

- In certain Cases, procedures run too quickly to get a central control to reply immediately. Using a decentralized controller it is potential to decrease lag, profiting in more uptime.

- It is Simple to connect if the device is local to this operator. This allows for capacities like trending analysis, alarming, batching, or printing.

- It may Be hard to troubleshoot when utilizing a single big system, instead of working on smaller ones. Distributed control applications is a lot easier to keep since there is less information to analyze.

- Field-based Distributed controls don’t entirely rely upon the central control. In case the central control goes into error, the whole procedure will not fail. This permits the user to keep on conducting their procedure.

- An excellent Advantage of owning a distributed system is that it is simpler to partition. You can have improved security utilizing zoned interlocks or mild guards.

In defense of this centralized system

There is a reason why a lot of individuals still use centralized systems. To start with, they’re proven over several years as an effective method of handling mill wide communications. Altering a system could be costly and counterproductive, why pose needless downtime if something already works nicely?

For new Gear, decentralization may add extra complexity that’s not needed. So in industries in which airborne particles or fever can lead to malfunction, a very simple installation with a conditioned centralized PLC is your better choice.

Most Importantly, you require a master on your system. This means one PLC that sends the master communications into the rest of your system. Usually, these are strong chips that spur messages off into smaller follower PLCs. What is great about this strategy is that we maintain control centralized, but profit from the freedom of individual areas of the system.

The linchpin of shift

Recently dimensions, communication, and application standards all influenced our decisions. They forced our hands when constructing gear. The options of this Industrial Internet of Things (IIoT) is going to be realized. Before long new companies will begin to look, offering the very same products but generating more smart products that boost uptime.

The question is, are you really prepared for another wave of invention and also the coming of the Era of the Industrial Internet of Things (IIoT)?